Trumpf / Huttinger TIG/BIG Induction Heaters

Over the 20 years, we have never seen TIG/BIG RF Induction Heater fail in the field! Never!, until our one in Aix-200RF reactor just stopped working in beginning of 2025.

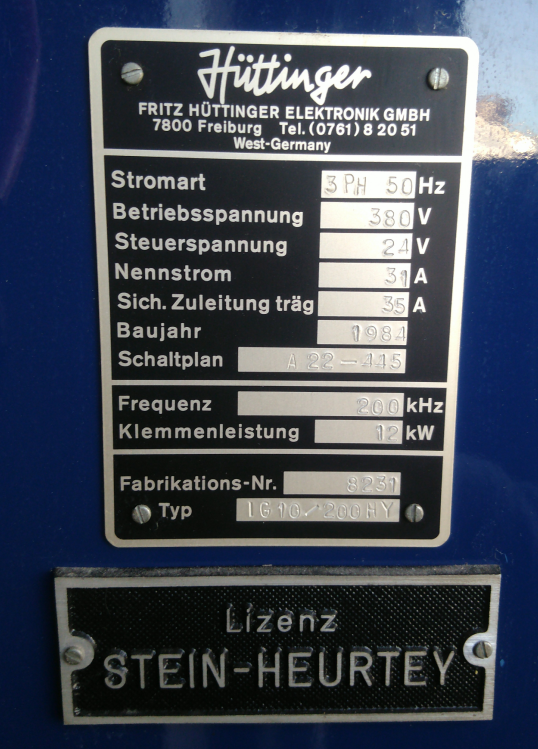

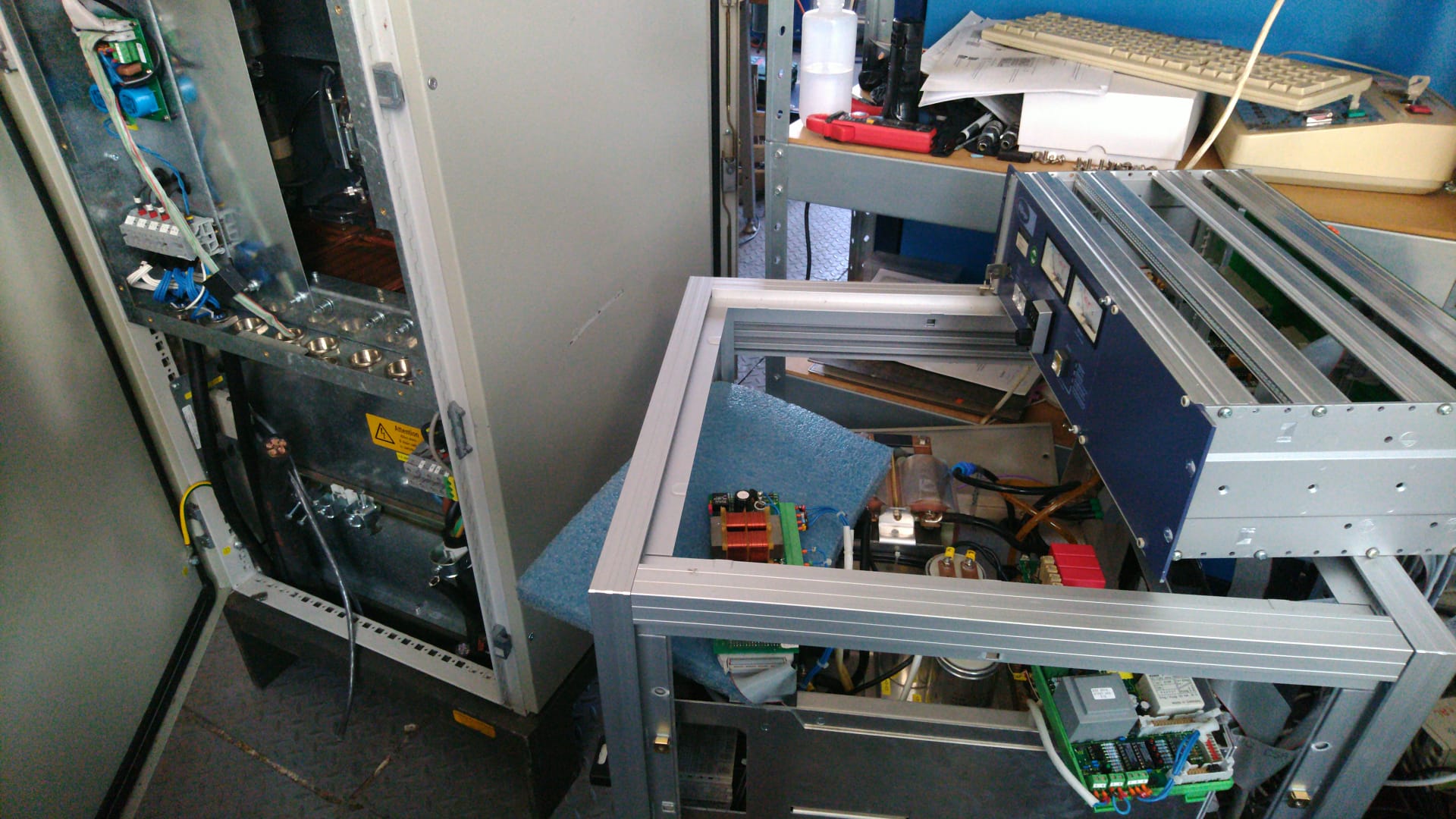

We have in total 4x Huttinger RF Induction Heaters. One of them venerable 42-years old hero manufactured in 1984, which served reliably for all those years in Aixtron nr 1 commercial reactor from 1985 (serial nr 1101/814), acquired from FZU.

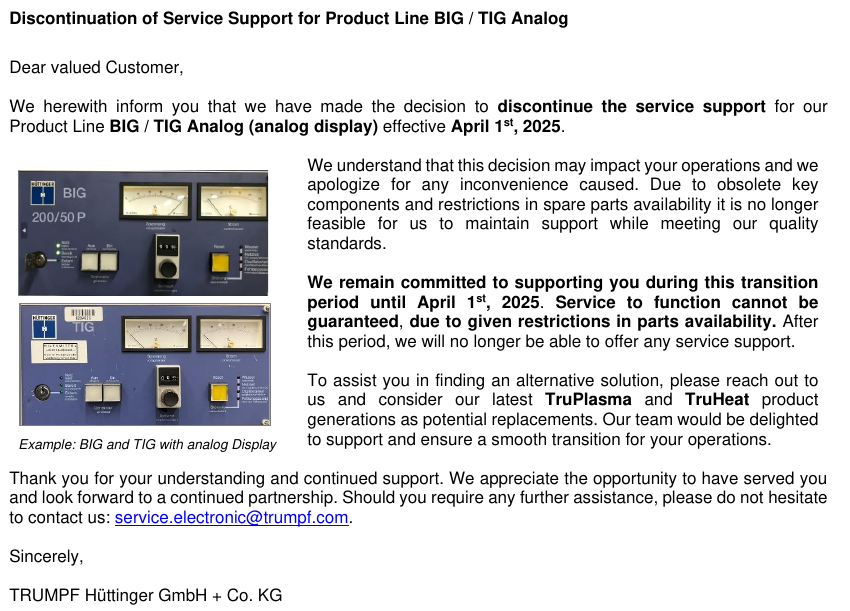

Trumpf EOL

In the first contact with Huttinger now Trumpf service team we learned, that our TIG heater are just at EOL for support in ~2months.

It was surprising to see how many variants and models of this induction

heaters were manufactured.

EOL see the

PDF

We had incomplete, poor quality paper documentation of our TIG, and

can’t obtain PDF version, so searching for clues and understanding in

paper documentation was long and painful.

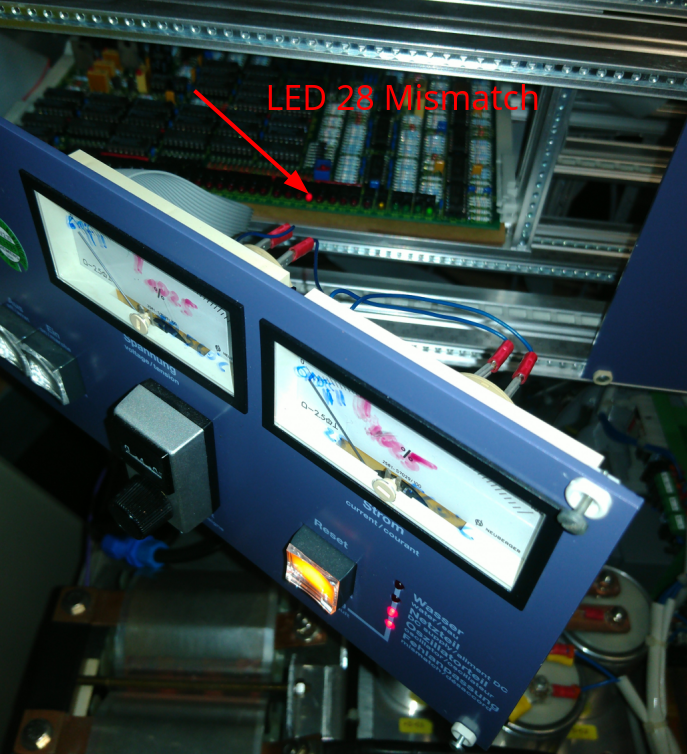

Weeks passed, our generator was disassembled to pieces, and still we

couldn’t find reason for “LED 28 Mismatch Error”.

To our surprise, despite production site for newer RF/HF generators in

Poland(Zielonka), there was no engineer in Poland, who know old analog

RF/HF generators, and we can’t get any service support in Poland from

Trumpf.

Getting Trumpf service engineer from Germany is very expensive. So

expensive, that it was difficult to justify it without running out of

all other options, and we were scrambling in panic against EOL

deadline.

Big thanks to CELEM capacitors team in France:

https://www.celem.com/Conduction_cooled_capacitors! If anyone need

reliable Induction Capacitors, CELEM is the right choice. They looked on

the pictures we sent in email, and told us straight, that their

capacitors are not root cause issue :-)!!

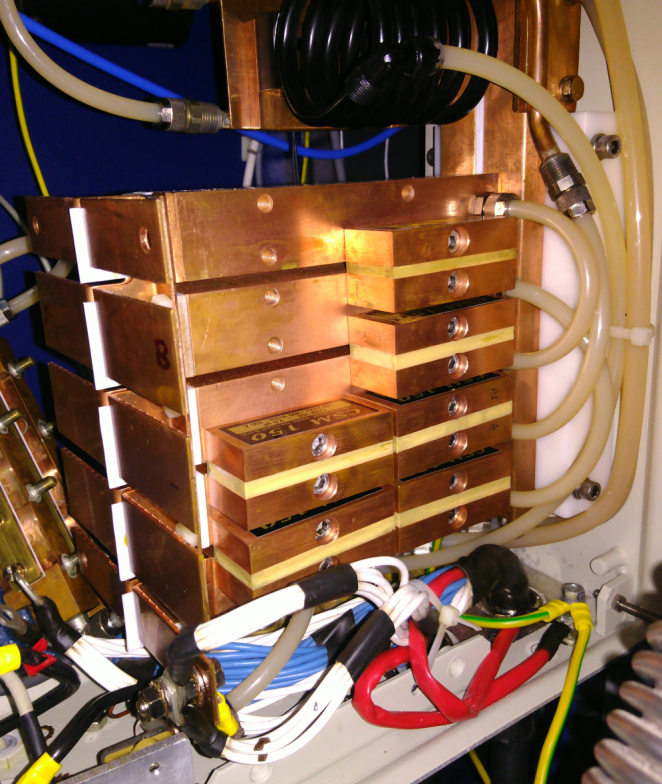

Of course we needed to be 100% sure, so we paid local CELEM distributor

company, to test them (they also wanted to take our TIG as “hostage” for

repair, but we decided to keep repairs on site, as were not impressed by

technical prowess of their local technicians).

Those marvelous tank capacitors, which every second get beating of

THOUSANDS!! of Volts, they just work! after 30 years in the field!!

WOW!!

Solution!!

After 2 months of attempts to repair, decided to change tactic, drop

repair for the time being, and just swap our TIG 10/100 to 2nd spare TIG

10/100 unit (though risky tactic, as 2nd one was never tested by us so

far, and standing in warehouse for emergency problems like this one

;/).

2nd unit turned out to be different inside: different PCBs, different

interconnections, some pins different on plugs.. all despite having the

same model brand name “TIG 10/100”. No so easy swap!!

We even dragged venerable 1984 hero as backup, and started to wire it up

for heat up test in parallel.. but..

Finally, after long 3 months of fighting, 2nd unit started to work!!

This was the biggest downtime we had so far.

Painful deep-tech lesson in RF heating.. but now we are way more

prepared to tackle quickly any problems with TIGs.

Key take away - EOL situation

So it is Aug 2025, and we are now on our own with 4x units of TIGs. The

TIG/BIG Huttinger Analog RF Generators are no longer supported, and we

work in background to get working 2nd and 3rd spare TIG/BIG.

We have some spare parts for them, and we believe that we will be able

to keep them working for a few years more.

Our insight suggest, that most frequently failures are located in the

Oscillator board, which we have now one original unit as spare.

We are devoted 6R “zeals”. We Refuse to throw away old equipment, and

make insane efforts to Repair and Recycle as much as possible.

As usual with old EOL equipment, users need to unite. If anyone has

problem with Trumpf Huttinger TIG/BIG Analog RF Generators for Induction

Heating, please lets get in touch.

After EOL all users are on their own, and need to build up network of

community users and local hands-on engineers support for such equipment.

Quick Comparison of MOCVD Heating Technologies

Over the 20 years of working with MOCVD reactors, we have been able to use in field all heating technologies applied by Aixtron. Induction is the best technology as we see it.

Nowadays, produced CCS and Planetary reactors use just three heating techs:

- Tungsten heaters in nitride and HT CCS reactors. Very fragile and delicate.

- Graphite heaters in As/P CCS reactors. Usually lifetime of a few years of industrial use.

- Induction heaters used in all Planetary reactors. Most reliable and convenient, but TC are to be replaced with pyrometers.

Older Horizontal reactors with quartz reactor tube and first generations

of Planetary reactors, used also IR halogen heaters, and Induction

heaters.

IR halogens require quite often replacements, but it is external and

outside of reactor tube, so it is just 1-2h of work to replace such

broken IR halogen lamp, but they disrupt straightforward in-situ

reflectance monitoring.

Planetary and CCS reactors are less efficient than horizontal reactor

technology, from energy consumption for heating/cooling point of view.

Their metal chambers are actively cooled down to ~30-60 degC, so cooling

capacity need to be larger than dissipated heating power. Heat and cool

reactor chamber at the same time. Heating graphite susceptor inside, and

at the same time cooling base plate, whole reactor walls and ceiling to

limit deposition on them.

In Aix-200 type of quartz reactors for As/P/Sb materials, there is no

such race between heating and cooling of chamber, the only cooled part

is RF Coil or IR reflectors, and reactor chamber is passively cooled by

air (sometimes with 1-2 fans to make sure o-rings works below

~60degC).

GaN Aix-200 though, have also cooled quartz chamber, as they could be

heated above 1200C, where quartz become soft, and active cooling by

water of quartz is necessary.