Have started GaSb buffer development with cleaving Ensemble3 GaSb Zn-doped substrate (bought from EVO-R funds) to 6 pieces, and running experiments.

In literature, not able to find info about the GaSb growth conditions with TMGa + TMSb, for Aix-200 type of reactor. There were a few excellent info, especially TEGa + TESb (which was also used by our partner FZU), and we used them as start point.

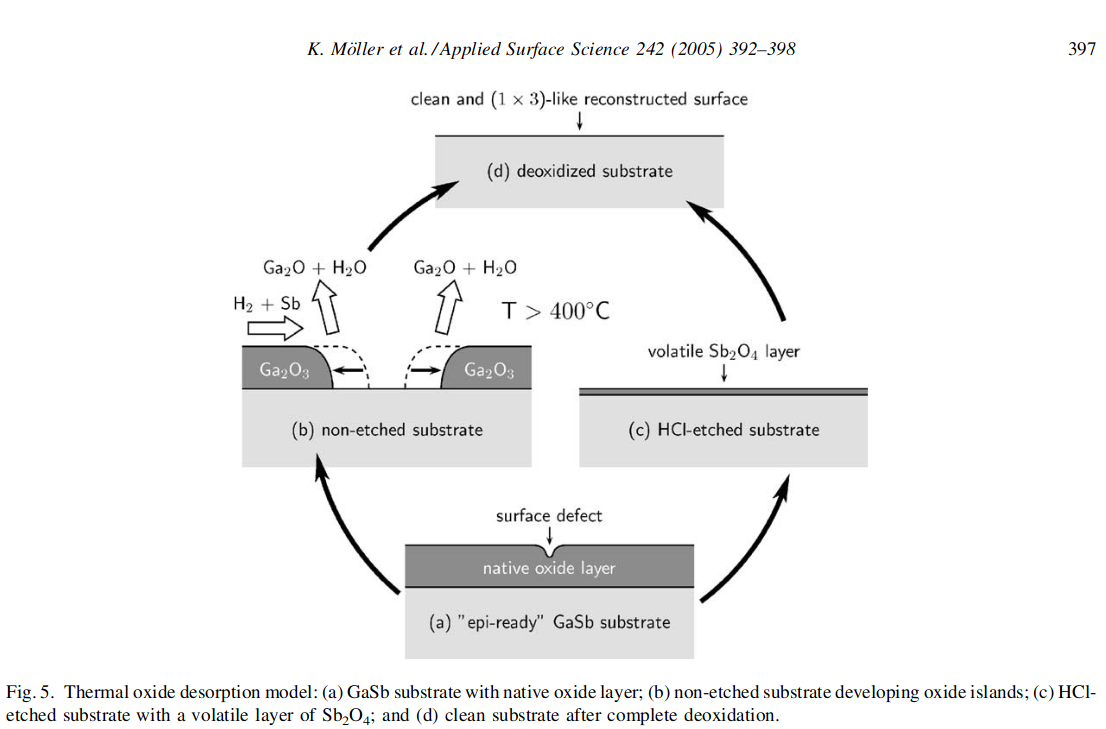

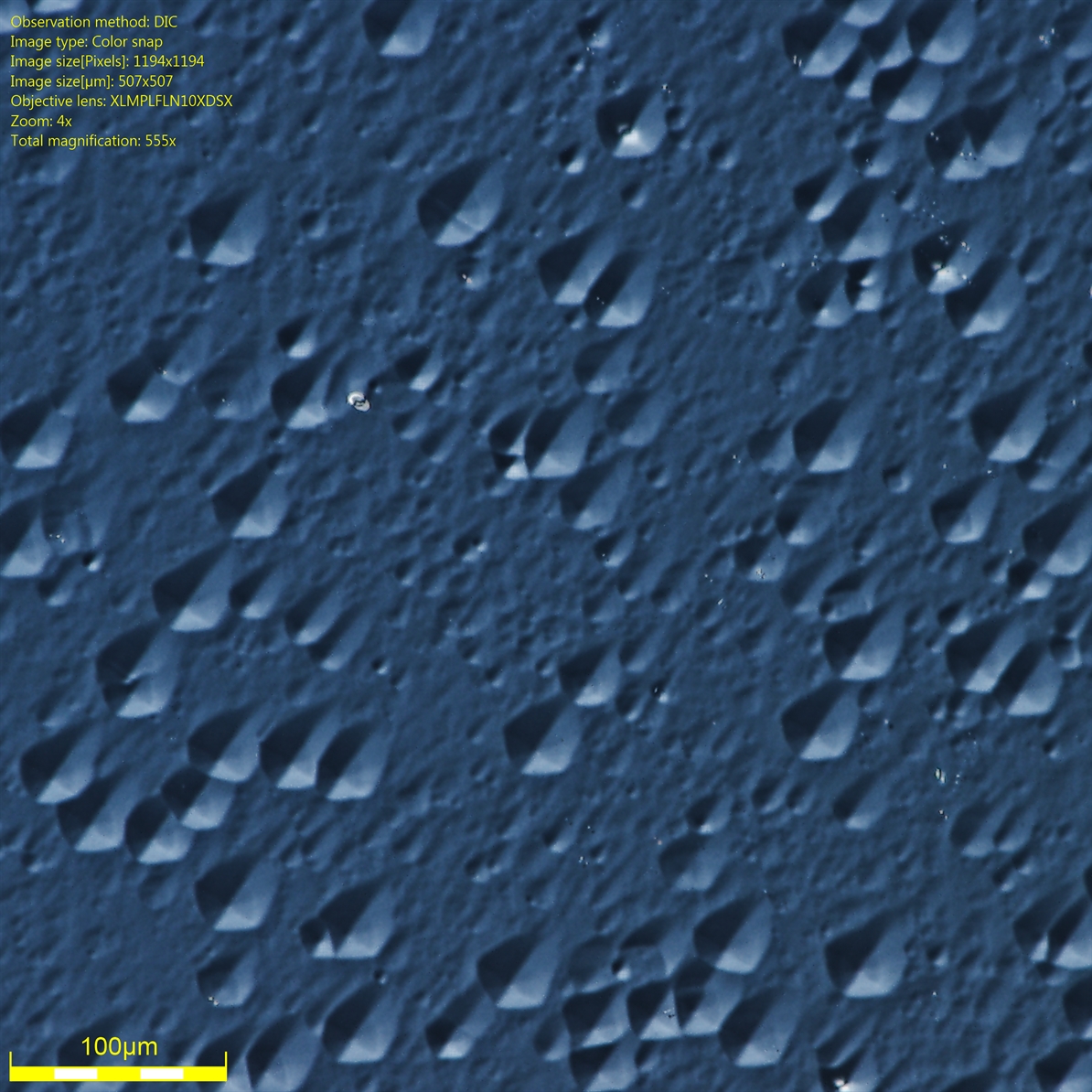

For preliminary parameter scan for GaSb optimization, decided to not etch substrates, so would get larger roughness and characteristic “oxide defects patterns”, but still the optimum V/III ratio should be clearly distinguishable.

Fig. 2. Nomarsky picture of surface with “the hillock” type of defects.

Fig. 2. Nomarsky picture of surface with “the hillock” type of defects.

Around the run nr 4 the faith, that 1 substrate will be enough to

optimize GaSb-on-GaSb buffers begin to tremble ;-), and we have split

two the biggest pieces in half to get 8 pieces in total, and increase

odds.

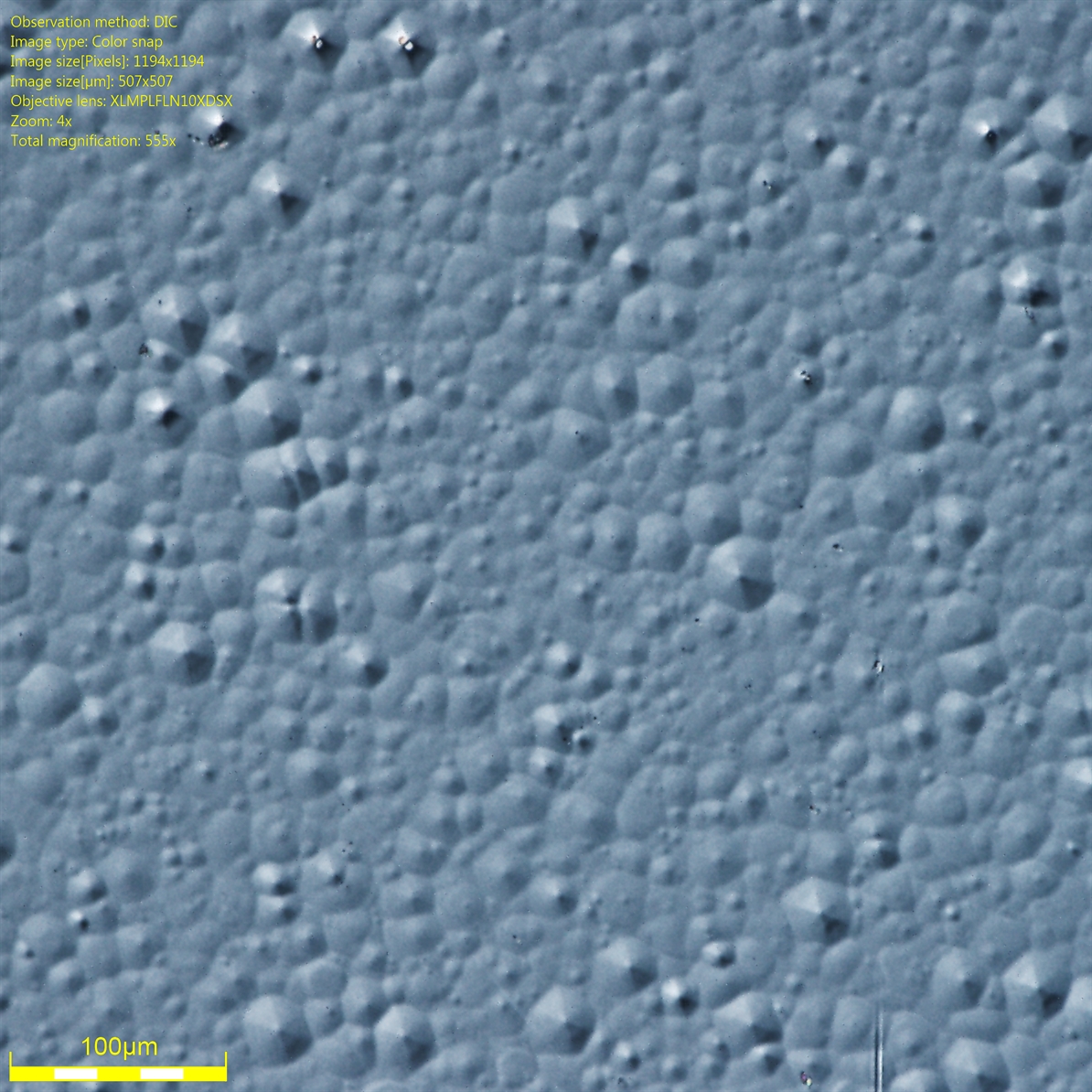

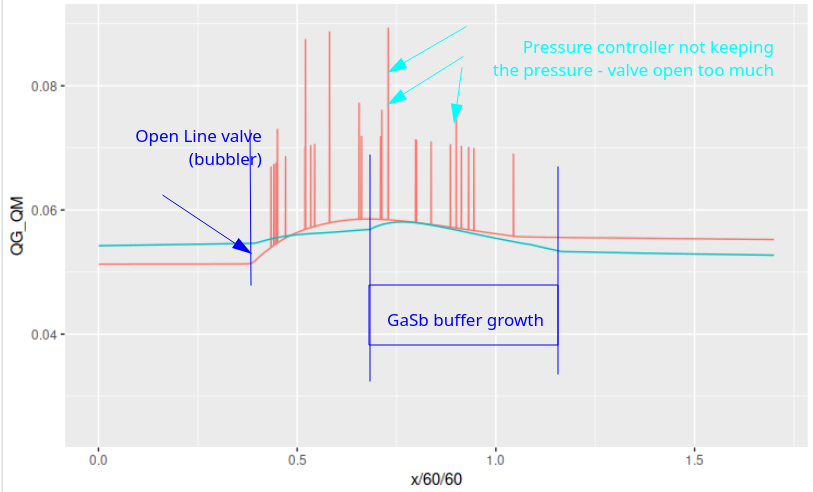

Also first runs indicated that the TMGa Pressure Controller is not

stable, and cause molar flow spikes.

Fig. 3 Construction of MFC/PC(left) and graph of log Sb/Ga ratio

recorded by 2x ultrasonic precursor monitors.

Fig. 3 Construction of MFC/PC(left) and graph of log Sb/Ga ratio

recorded by 2x ultrasonic precursor monitors.

Photin have dozens of spare Pressure Controllers (PC), and 3rd

replacement worked ok, not showing spikes in graphs of molar flow. This

kind of spikes (caused by too large opening of valve), could cause

complete disaster especially, for ultrasonic monitors in closed-loop

control mode with PID control (Episons). Our ultrasonic monitors do not

have PID, so it would be less problems, but still it is better to have

PC working without issues. This kind of problems with PC, are difficult

to detect without ultrasonic monitors.

Eventually, narrowed down the optimum GaSb buffer parameters with one

substrate, in 8 runs, ~1 week.

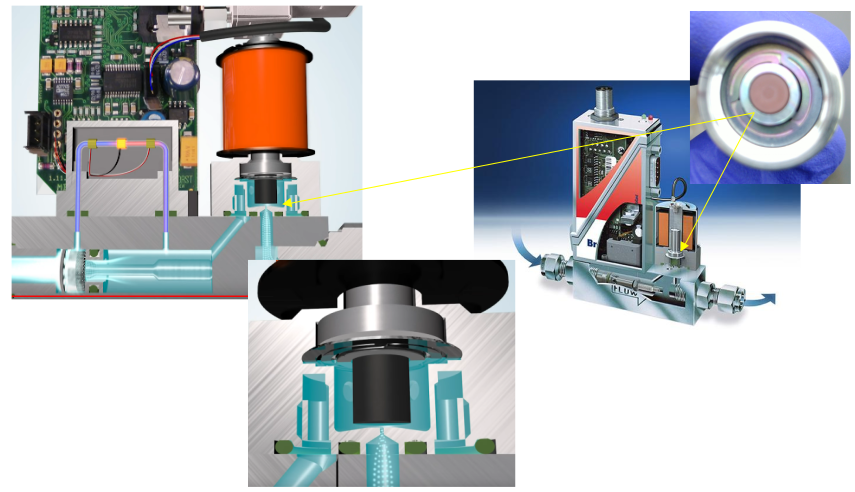

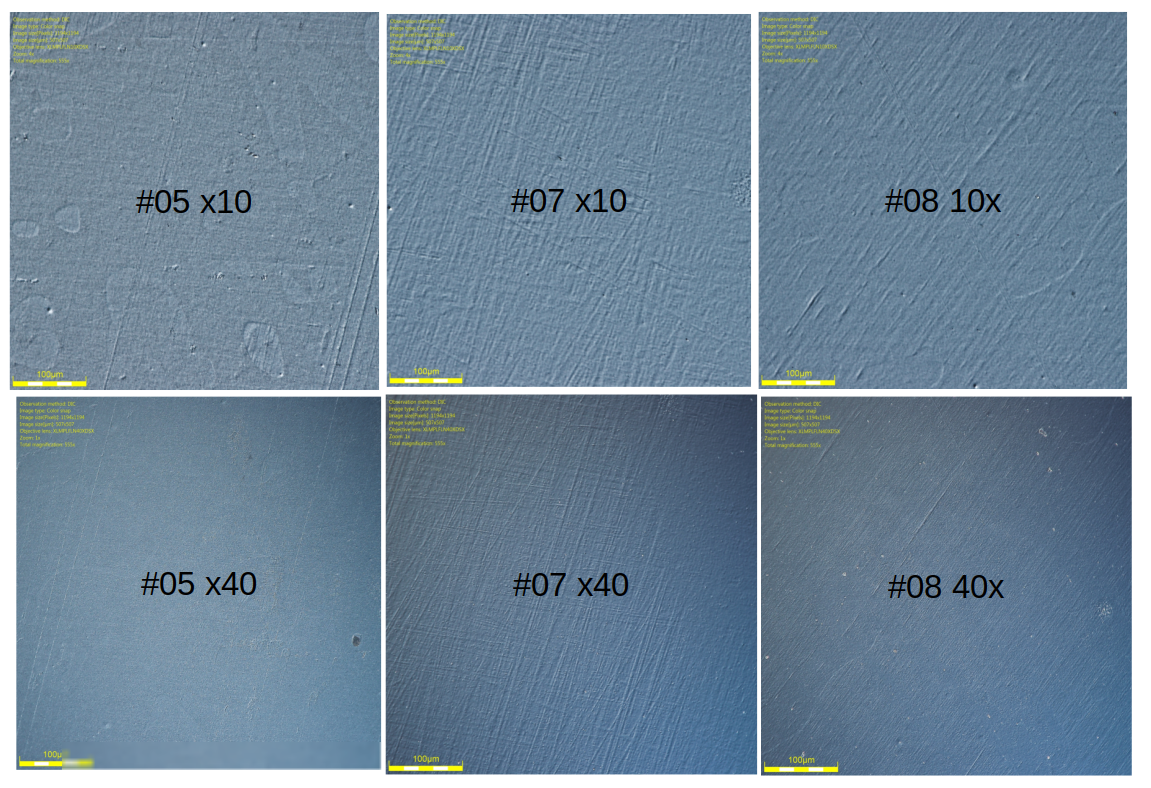

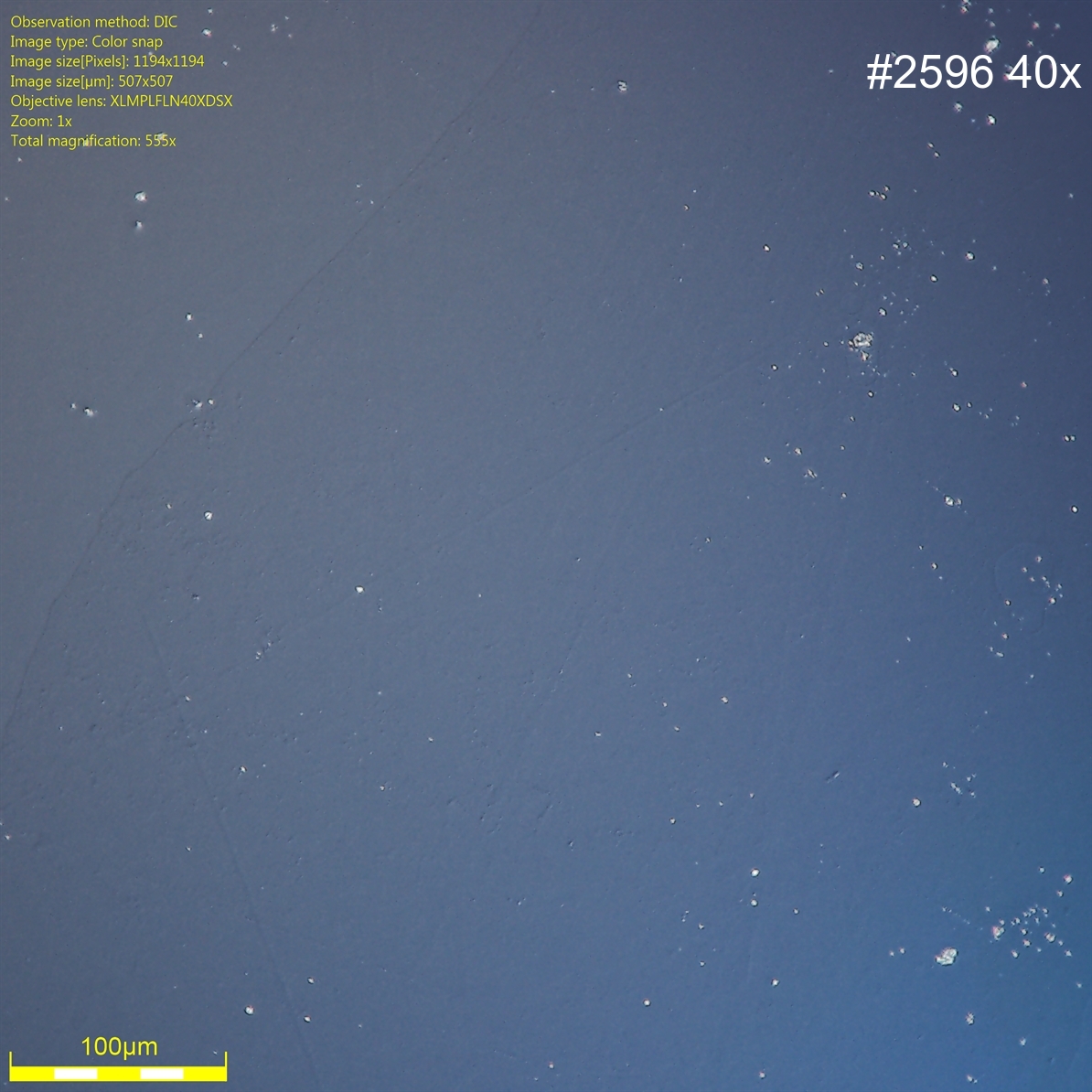

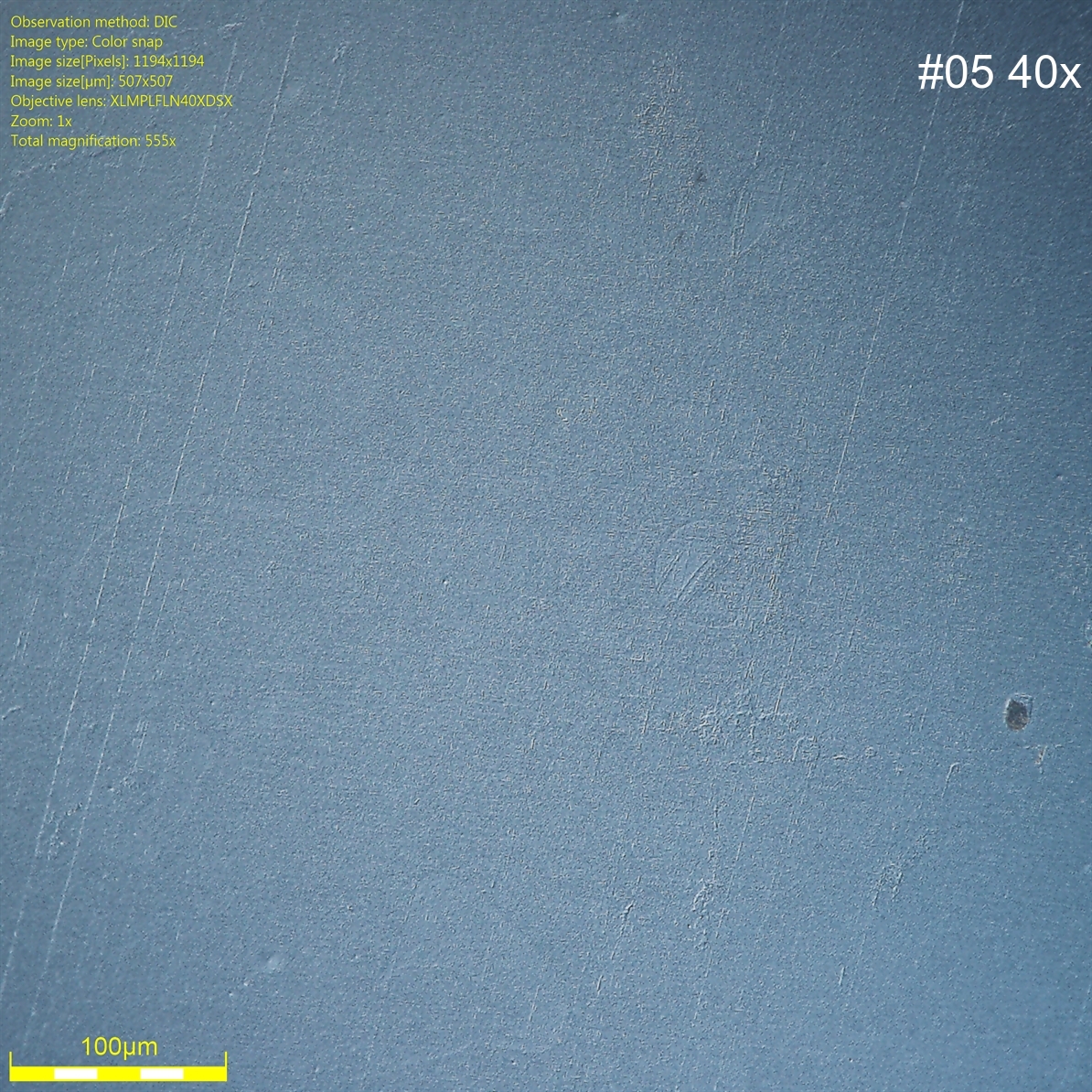

Fig. 3. Comparison of pictures taken by microscope with Nomarsky

contrast.

Fig. 3. Comparison of pictures taken by microscope with Nomarsky

contrast.

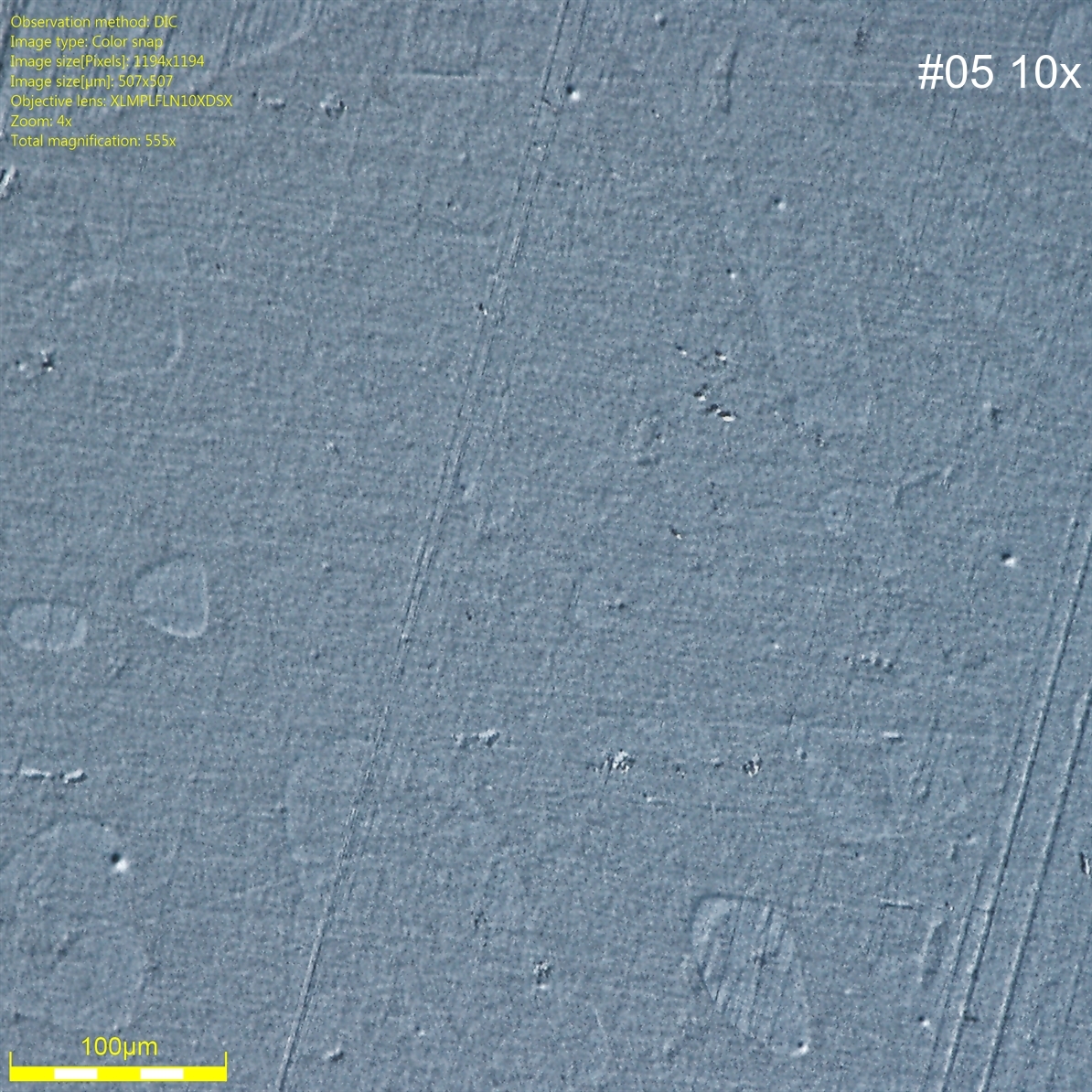

As could be seen, in run nr #5 set proper Sb / Ga ratio, then explored

going into a little Ga-rich buffers #7 and #8 to make sure, that

optimal Sb /Ga ratio was found. Pictures shows that run nr #5 had best

surface smoothness.

Key take away, is:

-

Te-rich GaSb give surface with hillocks patterns,

-

Ga-rich GaSb give streaky lines, that transition into Ga droplets on surface,

-

establishing proper Ga / Sb ratio for TMGa + TMSb in our reactor,

-

ability to keep and reproduce exactly optimum Ga / Sb ratio with help of ultrasonic monitoring devices.

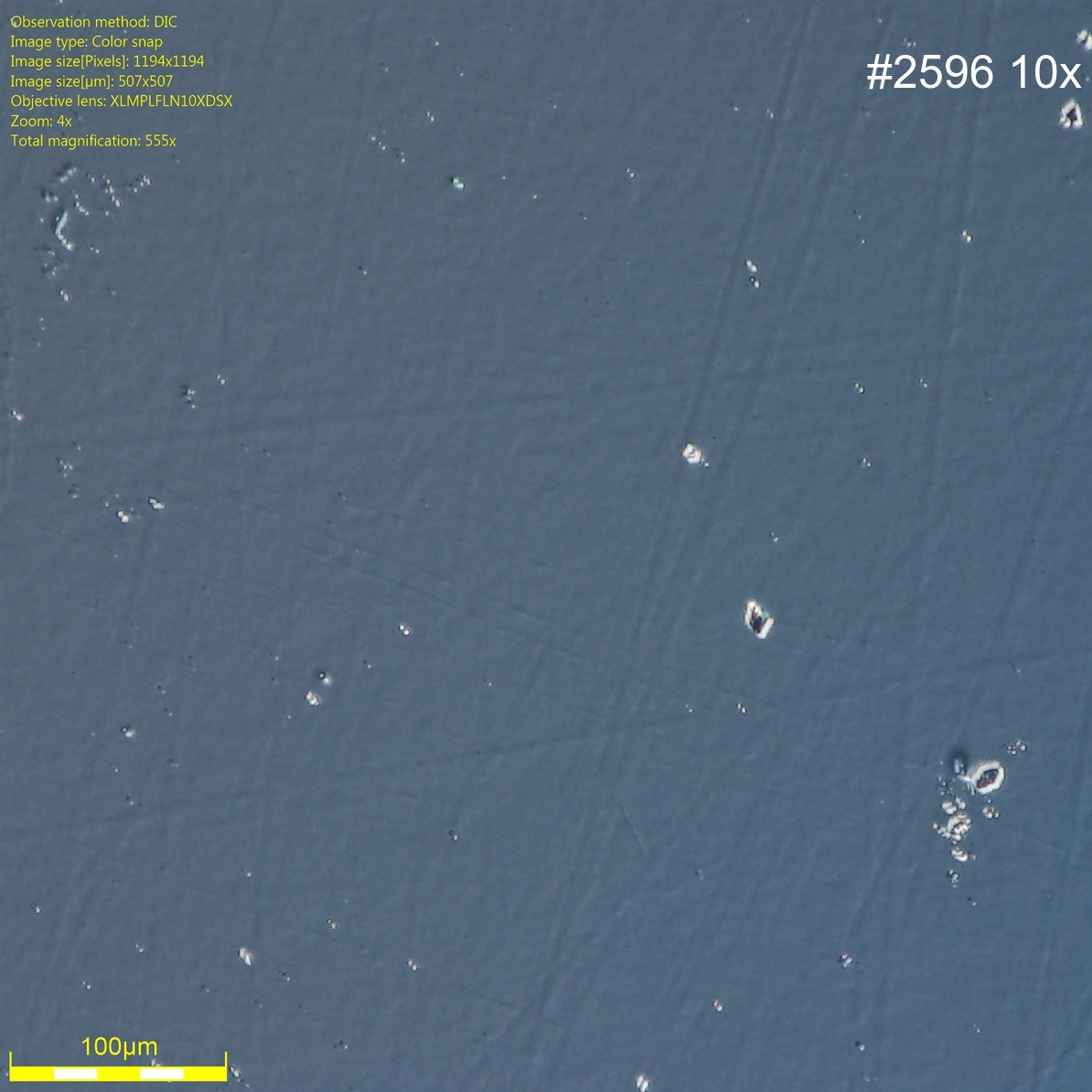

Comparing side by side buffers grown by FZU (TEGa + TESb, substrate HCl etched before loading) with buffers grown by Photin (TMGa + TMSb, not etched substrates).

We do not look on dots, points and other small defects, as they are

cleaving dust or substrate preparation. We look on smoothness of

surface, Nomarsky contrast with HDR is extremely sensitive to rough

surface.

It could be seen, that FZU grown buffers on etched substrates have

smoother surface, not etched substrates give “higher grain texture”.

Next steps will be:

-

Etch GaSb substrate, and grow thicker buffer, to narrow down optimum growth conditions, and confirm with AFM

-

Test GaSb buffers on GaAs

-

Ternary AlGaSb, InGaSb, AsGaSb

-

Test buffers with TEGa + TESb

…